With rising energy costs and increasing concerns about environmental sustainability, selecting the appropriate wall insulation for domestic building construction has become a crucial decision for builders and homeowners alike. The choice of insulation material can significantly impact a building’s thermal performance, reducing heat loss in winter and minimizing heat gain during summer months. For instance, consider a hypothetical case study where two identical houses are built side by side – one with proper wall insulation and the other without any insulation. It is highly likely that the insulated house would require less energy consumption for heating or cooling purposes compared to its non-insulated counterpart.

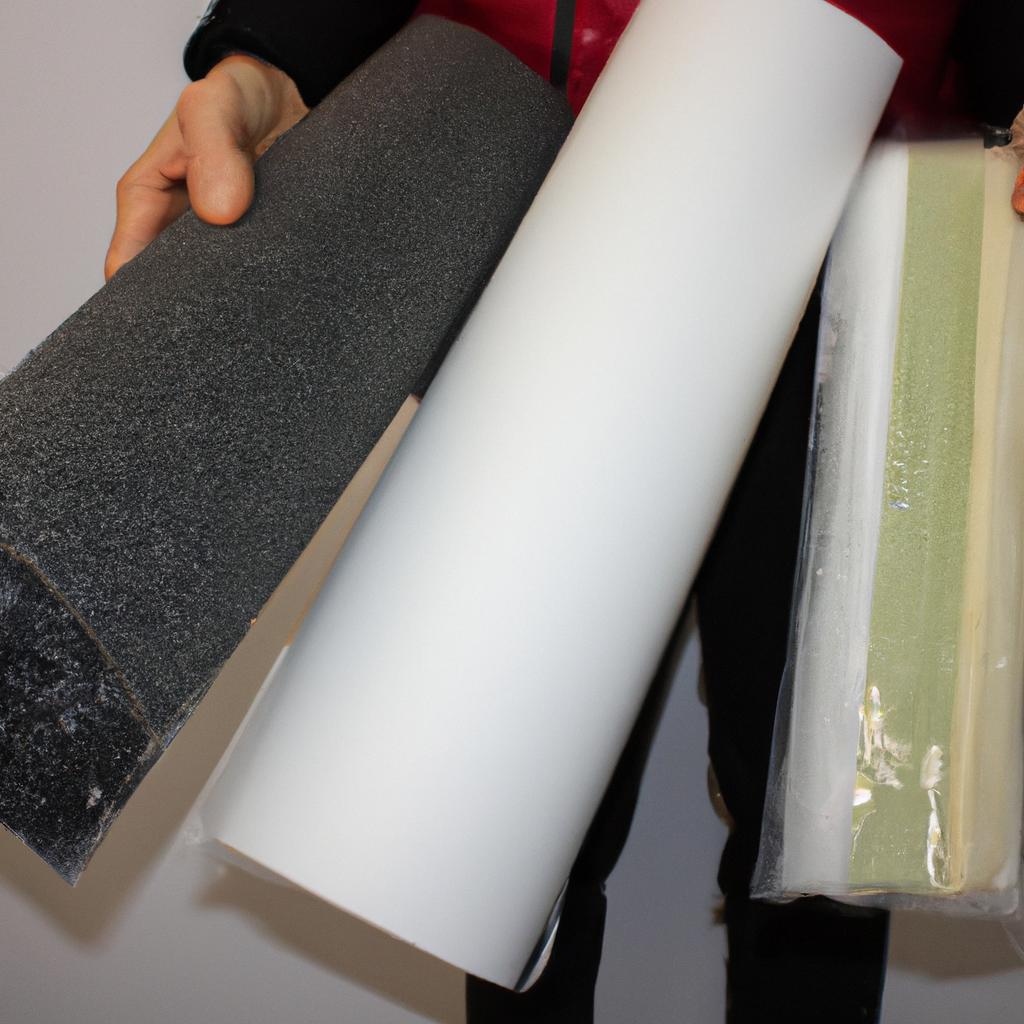

This article aims to provide an informative guide on various types of wall insulation materials commonly used in domestic buildings. By understanding their characteristics, advantages, and limitations, readers will be equipped with the knowledge necessary to make informed decisions when it comes to choosing the most suitable option for their specific needs. From traditional options such as fiberglass batts and mineral wool to newer alternatives like spray foam and rigid foam boards, each type of insulation offers distinct properties that cater to different requirements of thermal efficiency, moisture resistance, fire safety, soundproofing capabilities, and overall cost-effectiveness. This comprehensive overview will enable individuals involved in the construction industry to navigate through the multitude of choices available and select an optimal solution that meets their specific needs and priorities.

Fiberglass batts, one of the most commonly used insulation materials, are known for their affordability and ease of installation. They consist of fine glass fibers that trap air pockets, providing excellent thermal resistance. However, they may not be as effective in preventing air leakage or moisture infiltration.

Mineral wool, made from rock or slag fibers, offers similar benefits to fiberglass batts but with improved fire resistance. It is also more resistant to mold and pests. However, mineral wool can be denser and heavier than other options, requiring careful handling during installation.

Spray foam insulation has gained popularity due to its ability to fill gaps and cavities completely. It provides an airtight seal and superior thermal performance compared to traditional materials. However, it can be more expensive and may require professional installation.

Rigid foam boards are another alternative that offers high insulating values. They are lightweight and easy to handle, making them suitable for both new construction and retrofit projects. Rigid foam also provides good moisture resistance properties.

Other options include cellulose insulation made from recycled paper products, which offers good thermal performance at a lower cost but may require additional fire-retardant treatment. Reflective foil insulation reflects radiant heat away from the building, making it ideal for hot climates but less effective in colder regions.

Ultimately, the choice of wall insulation material depends on factors such as climate conditions, budget constraints, sustainability goals, local building codes, and personal preferences. Consulting with professionals in the field can provide valuable insights and help determine the best option for each specific project.

By considering these various types of wall insulation materials along with their characteristics and suitability for different requirements, builders and homeowners can make informed decisions that contribute to energy efficiency while ensuring comfort and long-term durability of domestic buildings.

Batt Insulation

Batt Insulation

One common type of wall insulation used in domestic building construction is batt insulation. This type of insulation consists of pre-cut fiberglass or mineral wool panels that are inserted between the studs and joists of a wall. It provides thermal resistance by trapping air pockets within its fibers, which helps to reduce heat transfer.

For instance, consider a hypothetical scenario where a family residing in a cold climate region wants to improve their home’s energy efficiency. They decide to install batt insulation in their exterior walls as part of their renovation project. By doing so, they aim to minimize heat loss during the winter months and create a more comfortable living environment for themselves.

To further understand the benefits of using batt insulation, let us examine some key advantages:

- Cost-effective: Batt insulation tends to be relatively affordable compared to other types of wall insulation materials.

- Ease of installation: The pre-cut panels can be easily installed without specialized equipment or professional assistance.

- Versatility: Batt insulation is available in various sizes and thicknesses, allowing it to fit different stud spacings and accommodate irregularities in wall surfaces.

- Soundproofing properties: In addition to providing thermal resistance, batt insulation also helps attenuate sound transmission, enhancing acoustic comfort within homes situated near noisy environments such as busy roads or airports.

| Pros | Cons |

|---|---|

| Cost-effective | Susceptible to mold |

| Easy installation | Limited moisture control |

| Versatile | Potential for gaps |

| Soundproofing | Reduced effectiveness |

In summary, batt insulation offers an economical solution for homeowners seeking improved thermal performance and sound reduction. Despite its advantages, however, it is crucial to address potential drawbacks such as susceptibility to mold growth if exposed to excessive moisture or inadequate installation leading to gaps.

Moving forward into the subsequent section on “Spray Foam Insulation,” we will explore an alternative approach to wall insulation that offers distinct benefits.

Spray Foam Insulation

Batt Insulation: A Reliable Choice

After discussing the benefits of batt insulation, we now turn our attention to another popular option in wall insulation – spray foam insulation. To further understand its characteristics and advantages, let us consider a hypothetical scenario. Imagine a newly constructed house located in a cold climate region where maintaining indoor warmth is crucial during winter months.

Spray Foam Insulation: An Efficient Solution

In this case, spray foam insulation proves to be an efficient solution due to several key factors:

- Superior Air Sealing: Spray foam insulation creates an effective air barrier by expanding rapidly upon application. This helps seal any gaps or cracks that may exist in the walls, preventing drafts and heat loss.

- High R-value: The R-value measures the thermal resistance of an insulating material, with higher values indicating greater effectiveness. Spray foam insulation boasts a high R-value compared to other types of insulation available on the market today.

- Moisture Resistance: Another advantage of spray foam insulation lies in its ability to resist moisture infiltration. By creating a tight seal against water vapor, it minimizes the risk of mold growth within the walls.

- Properly installed spray foam insulation can reduce energy costs by up to 50%.

- Its superior air sealing properties contribute to improved indoor air quality.

- By reducing heat loss and gain, spray foam insulation enhances overall comfort levels.

- It provides long-term performance with minimal maintenance requirements.

Additionally, we have provided a table below comparing spray foam insulation with other common methods used for wall insulation:

| Batt Insulation | Spray Foam Insulation | |

|---|---|---|

| Installation | Relatively easy | Requires professional expertise |

| Efficiency | Moderate | High |

| Moisture | Susceptible | Resistant |

| Lifespan | 20-30 years | Over 50 years |

As we can see, spray foam insulation offers notable advantages over batt insulation in terms of air sealing, energy efficiency, and moisture resistance. This makes it a preferred choice for homeowners seeking optimal thermal performance.

Transitioning into the subsequent section about “Loose-Fill Insulation,” let us now explore another alternative for wall insulation that presents its own unique set of benefits.

Loose-Fill Insulation

Spray Foam Insulation

After exploring the benefits and considerations of spray foam insulation, let us now delve into another commonly used type of wall insulation: loose-fill insulation. Imagine a scenario where you have an older home with uneven stud spacing and irregularly shaped cavities to insulate. In this situation, loose-fill insulation can be an effective solution.

Loose-fill insulation is made up of small particles or fibers that are blown or poured into wall cavities using specialized equipment. These particles fill all the gaps and voids within the cavity, providing excellent thermal resistance and reducing air leakage. One example of loose-fill insulation is cellulose fiber – a popular choice due to its affordability, high R-value (thermal resistance), and eco-friendliness as it is often made from recycled newspaper.

Here are some key advantages of utilizing loose-fill insulation:

- Enhanced energy efficiency: Loose-fill insulation creates a continuous layer without any gaps, preventing heat transfer and reducing energy consumption.

- Soundproofing properties: The dense nature of loose-fill insulation helps absorb sound vibrations, improving acoustic comfort in your living space.

- Fire retardant qualities: Certain types of loose-fill materials, such as mineral wool, possess inherent fire-resistant properties which contribute to overall safety.

- Environmentally friendly option: Many loose-fill materials consist of recycled content, making them sustainable choices for environmentally-conscious homeowners.

| Material | R-value per inch | Cost (per square foot) | Environmental Impact |

|---|---|---|---|

| Cellulose | 3.6-3.8 | $1-$1.50 | High |

| Fiberglass | 2.2-2.7 | $0.80-$1 | Moderate |

| Mineral Wool | 3.0-4.0 | $1-$2 | Moderate |

| Spray Foam | 6.0-7.0 | $2-$3 | Low |

Moving forward, let us explore yet another widely used type of wall insulation: rigid foam insulation.

Transition Sentence: With an understanding of the benefits and considerations associated with loose-fill insulation, we now turn our attention to exploring the characteristics and advantages of rigid foam insulation in domestic building construction.

Rigid Foam Insulation

Continuing our exploration of wall insulation types, we now turn our attention to rigid foam insulation. As the name suggests, this type of insulation is composed of solid panels or boards made from materials such as polystyrene, polyurethane, or polyisocyanurate. To better understand its application and benefits, let us consider a hypothetical scenario:

Imagine a newly constructed residential building located in an area with extreme temperature fluctuations throughout the year. The architects and builders decide to utilize rigid foam insulation due to its high insulating properties and durability. By incorporating this material into the walls, they aim to create a comfortable indoor environment while reducing energy consumption.

Rigid foam insulation offers several advantages that make it a popular choice in domestic building construction:

- Superior thermal resistance: With an R-value (a measure of thermal resistance) typically ranging between 4 and 8 per inch, rigid foam insulation provides excellent heat flow resistance compared to other types.

- Moisture resistance: Thanks to its closed-cell structure, rigid foam effectively repels moisture infiltration, which helps prevent mold growth and structural damage caused by water absorption.

- High compressive strength: Due to its dense composition, rigid foam can withstand heavy loads without significant deformation or loss of insulating properties.

- Versatile installation options: Whether used as exterior sheathing or interior wall insulation, rigid foam can be easily cut and shaped to fit different spaces and accommodate various architectural designs.

To further illustrate the differences between loose-fill insulation discussed earlier and rigid foam insulation, let us examine them side by side in the following table:

| Property | Loose-Fill Insulation | Rigid Foam Insulation |

|---|---|---|

| Thermal Resistance | Moderate | High |

| Moisture Resistance | Requires additional treatment | Excellent |

| Compressive Strength | Low | High |

| Installation Flexibility | Limited | Versatile |

As we can see, rigid foam insulation offers distinct advantages over loose-fill insulation in terms of thermal resistance, moisture protection, compressive strength, and installation flexibility.

By adopting a reflective approach to heat transfer, this type of insulation presents unique benefits that complement those provided by both loose-fill and rigid foam insulation methods.

Reflective Insulation

Rigid Foam Insulation

In the previous section, we explored the benefits and applications of rigid foam insulation in domestic building construction. Building upon this knowledge, let us now delve into another popular type of wall insulation: reflective insulation.

Reflective insulation is designed to resist radiant heat transfer by reflecting it away from the surface. This type of insulation typically consists of a highly reflective material, such as aluminum foil, laminated onto a substrate material like plastic or cardboard. To illustrate its effectiveness, consider a hypothetical scenario where a house located in a hot climate has reflective insulation installed on its walls. As the sun’s rays beat down on the external surfaces of the house, the reflective insulation would help keep the interior cool by reflecting much of that radiant heat back outside.

Now let us explore some key characteristics and advantages associated with reflective insulation:

- Reflective properties: The primary function of reflective insulation is to reflect radiant heat rather than absorb it. This property allows for effective temperature regulation within buildings.

- Energy efficiency: By reducing heat gain during summer months and minimizing heat loss during winter months, reflective insulation can contribute to energy savings and lower utility bills.

- Easy installation: Reflective insulations are often lightweight and easy to install due to their flexible nature. They can be rolled out or cut into desired shapes without requiring specialized tools or equipment.

- Durability: High-quality reflective insulations offer long-term performance and durability when properly installed and maintained.

To further emphasize these points, here is an emotional bullet point list highlighting how reflective insulation can positively impact homeowners:

- Lower energy consumption leads to reduced carbon footprint

- Improved comfort levels throughout all seasons

- Potential cost savings on heating and cooling expenses

- Enhanced indoor air quality through better thermal control

Additionally, please refer to the following table for a visual representation comparing different types of wall insulations based on various criteria:

| Rigid Foam Insulation | Reflective Insulation | |

|---|---|---|

| Material | Foam boards | Reflective foil |

| Installation | Requires professional | Easy DIY installation |

| Insulating Value | High | Moderate |

| Cost | Relatively expensive | Affordable |

With these advantages and considerations in mind, it is evident that reflective insulation offers an effective solution for controlling heat transfer within residential buildings. In the subsequent section, we will explore another noteworthy type of wall insulation: Insulated Concrete Forms (ICFs).

Insulated Concrete Forms (ICFs)

Reflective Insulation is just one of the many types of wall insulation used in domestic building construction. In this section, we will explore another popular option known as Insulated Concrete Forms (ICFs). To better understand its benefits and applications, let’s consider a hypothetical scenario where homeowners are looking to build an energy-efficient house in a cold climate.

Insulated Concrete Forms (ICFs) offer excellent thermal performance by utilizing insulating foam boards that form the structure of exterior walls. These forms are stacked together and filled with concrete, creating a solid and well-insulated wall system. The result is a highly efficient envelope that minimizes heat loss or gain from the outside environment.

Here are some key advantages of using ICFs:

- Superior insulation: The combination of insulating foam boards and concrete provides exceptional thermal resistance, helping to maintain stable indoor temperatures year-round.

- Energy efficiency: By significantly reducing air infiltration and heat transfer, ICFs can greatly lower heating and cooling costs for homeowners.

- Enhanced soundproofing: The dense composition of ICF walls helps to minimize noise transmission from external sources, ensuring a quiet living environment.

- Increased durability: ICF structures are resistant to damage from fire, moisture, pests, and extreme weather conditions such as hurricanes or earthquakes.

To illustrate the potential benefits further, consider the following table comparing the average annual energy costs between conventional wood-framed houses and homes constructed using ICFs:

| Wood-Framed House | ICF House | |

|---|---|---|

| Heating | $1,200 | $600 |

| Cooling | $800 | $400 |

| Total Annual Cost | $2,000 | $1,000 |

As shown above, homeowners could potentially save up to 50% on their annual energy expenses by opting for an ICF construction method. This not only results in significant cost savings but also reduces the environmental impact associated with excessive energy consumption.

In summary, Insulated Concrete Forms (ICFs) offer a highly efficient and durable wall insulation option for domestic building construction. The combination of insulating foam boards and concrete provides excellent thermal performance, energy efficiency, soundproofing, and increased resilience to various hazards. By choosing ICFs over conventional building methods, homeowners can enjoy substantial savings on their energy costs while creating a comfortable and sustainable living space.